Certifications and ERDF projects

ISO 9001:2015 certificate

Scope of certification:

Construction, maintenance, upgrading, new development and commissioning of technical systems and components mainly in connection with pumps, valves, compressors and motors for use in industrial and power plant applications, the mineral oil, petrochemical and natural gas industries, ship building and steel construction and the dismantling of nuclear installations

ISO 14001:2015 certificate

Scope of certification:

Construction, maintenance, upgrading, new development and commissioning of technical systems and components mainly in connection with pumps, valves, compressors and motors for use in industrial and power plant applications, the mineral oil, petrochemical and natural gas industries, ship building and steel construction and the dismantling of nuclear installations

SCC**-VAZ 2021 certificate

Scope of certification:

Bau, Instandhaltung, Optimierung, Neuentwicklung und Inbetriebnahme technischer Systeme und Komponenten mit den Schwerpunkten Pumpen, Armaturen, Verdichter und Antriebe in der Industrie und Kraftwerkstechnik, der Erdöl-, Petrochemie- und Erdgasindustrie, dem Schiff- und Stahlbau, Rückbau kerntechnischer Anlagen, Industrie- und Kraftwerkstechnik, der Erdöl-, Petrochemie- und Erdgasindustrie, dem Schiff- und Stahlbau, Rückbau kerntechnischer Anlagen

SCP-VAZ 2021 certificate

Scope of certification:

Labour leasing for construction, maintenance, and commissioning of technical systems and

components for use in industrial and power plant applications, the mineral oil, petrochemical and natural gas industries,

ship building and steel construction and the dismantling of nuclear installations

DIN EN ISO 3834 certificate

ISO 3834-2 – Lubmin

MAL Maschinen- und Armaturenwerkstatt Lubmin GmbH meets the high requirements of ISO 3834-2 for comprehensive quality requirements in fusion welding of metallic materials at its Lubmin site. This certification confirms the structured, safety-oriented, and reproducible execution of all welding processes. For our customers, this means maximum reliability, tested manufacturing quality, and consistently high standards at every step of production.

ISO 3834-2 – Stralsund branch

Our Stralsund branch is also certified according to ISO 3834-2. This certificate underscores the consistent implementation of quality-assured welding processes at both company locations. By complying with internationally recognized standards, we guarantee consistently high-quality metal processing, qualified specialist personnel, and documented quality management for demanding technical projects

AD 2000 HP 0/ HP 100R certificate

We apply a product-related quality assurance system, has facilities to process the materials properly and to carry out the necessary tests. He has his own responsible supervisory personnel as well as competent personnel for the production.

We apply a quality assurance system to prepare, permanently join and test components for pressure equipment in such a way that the safety of the pressure equipment is not impaired and its traceability is guaranteed. The welding specifications were checked with test basis DIN EN ISO 3834 part 3 related to the manufacture of pressure equipment.

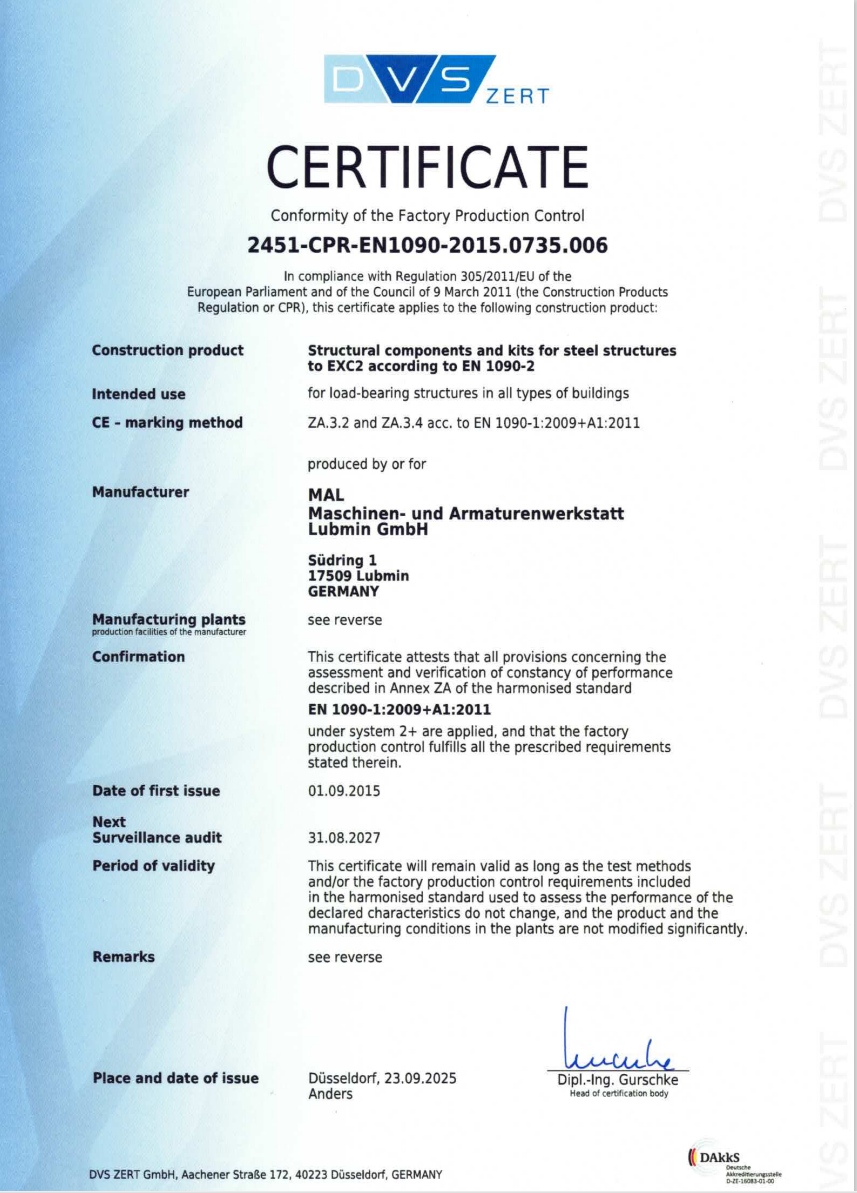

EN 1090-2 certificate

EN 1090-2 (EXC 2)

With EN 1090-2 certification in execution class EXC 2, MAL Maschinen- und Armaturenwerkstatt Lubmin GmbH is qualified to manufacture load-bearing steel and aluminum components in accordance with European construction product requirements. This certification confirms our manufacturing expertise in structural steel construction, the controlled execution of safety-relevant components, and compliance with all legally prescribed performance and verification procedures.

EN 1090 - Welding Certificate

The EN 1090 welding certificate confirms our professional competence to carry out welding work on load-bearing components in steel and metal construction. Through tested welding procedures, qualified personnel, and a monitored manufacturing process, MAL Maschinen- und Armaturenwerkstatt Lubmin GmbH creates the basis for maximum manufacturing safety. Customers benefit from welding work that is demonstrably compliant with standards and reliable project execution.

Certificate of conformity for factory production control

electrical contractor

We are an electrical contractor.

ATEX - approval

We are ATEX certificed.

Certificates

Overall, industry certificates offer an opportunity to prove the quality, safety and conformity of products and services and at the same time strengthen competitiveness and trust in companies.

European research and funding projects ERDF

Feasibility studies are crucial to ensure that ERDF funding is used effectively and that the projects funded make a positive contribution to the development and promotion of innovation. They provide a sound basis for making informed decisions about investing resources in promising.

Project No.: TBI-V-2-127

The aim of the feasibility study is to develop one or more test methods including the necessary technology for testing and evaluating the actual condition of the container surfaces and the structural material of waste containers for radioactive residues.

It is to be examined whether it is feasible to determine the actual condition of the containers using a technical procedure without exposing the inspection personnel to ionizing radiation, as opposed to conventional visual inspection.

Project no.: TBI-5-007

Das Ziel der Prozessinnovation ist, Teile des Prüfprozesses des Maschinenbaus

richtlinienkonform zu überführen, die technische Organisation im Unternehmen dahingehend anzupassen und spezialisierte Prüfstände digital zu transformieren.

Des Weiteren soll die Fertigungstiefe in den Bereichen Reinigung und der Ersatzfertigung,

insbesondere von Wellen und Kolben, erhöht werden.

The introduction of various digital processes is required to achieve the project objectives.

Dazu zählen die Umstellung und Anpassung der IT-Struktur sowie weitgehende Auf- und Umrüstung der Fertigungskomponenten für eine digitale Vernetzung, die digitale Erfassung der Wucht- und Prüfergebnisse und Übertragung in entsprechende

Nachweisformulare sowie die Übertragung der erstellten Fertigungszeichnungen an die

entsprechenden Fertigungsmaschinen, um eine Teilautomatisierung gewisser Abläufe zu erreichen.

Project No.: TBI-6-006

The aim of the investment project is to introduce a precision lathe to increase the vertical range of manufacture in the company.

With the commissioning of the precision lathe, it will be possible to increase the quality of the products and services and thus strengthen

the competitiveness of the company.

By increasing quality, the company can win new orders or better serve existing customers. It also makes it possible to open up new markets or

diversify its own product range.

The precision lathe will enable the company to achieve qualitative improvements in the production of wear and spare parts as

well as its own products. This enables us to produce more complex

geometries and to acquire additional orders.

project number: : TBI-1-135-U-041

The joint R&D project aims to develop an innovative, remote-controlled process for the automated condition monitoring of Konrad containers. The new system is designed to ensure that a complete and objective inspection of all external surfaces of the containers can be carried out without the need for relocation or the immediate presence of inspectors.

In the R&D consortium, an innovative, functional overall system for remote-controlled testing is being designed, implemented in an iterative process in the form of test samples, and evaluated under realistic conditions in terms of technical suitability and regulatory connectivity.

Our company is involved in the development of a remote-controlled process for the automated condition monitoring of containers for the interim storage of non-heat-generating radioactive waste (Konrad containers). To this end, we carry out the necessary R&D activities for system analysis, technology selection, the design of suitable processes, and preparation for subsequent approval.